This article is written by the Chartered Institute of Supply Chain Management – Ghana (CISCM), of which I am an Eminent Member and Subject Matter Expert on Innovations & Business Development.

The Core Principles of ISCM

- The Concept of the Remote Cause – This is referred to as the principle of ensuring that before any activity is done, there must be a conscious and detailed review of all established norms, processes, and procedures to gain wholistic understanding of the environment within which an activity, decision, and/or action is taken. This can also be referred to as the source of the source of the sources. The essence of doing this is to ensure the attainment of efficiency and optimization which result in Absolute Value.

- The Concept of Absolute Value – This also refers to the actual gain that an activity, decision and/or action results in. This can be called the actual life-cycle composite gain because it has direct correlation to;

- Predictive results – The maximum returns

- Progressive results – The accelerated rate of returns which is devoid of regression

- Sustainable results – The returns of a life-cycle (business or project)

But at all times, the primary objective is to achieve sustainable results.

- The Iceberg principle – This principle refers to the thorough diligence and critical mindset needed in Integrated Supply Chain Management because, invariably, visible things carry a far bigger unseen or hidden factors. Generally, it is said of an Iceberg that, the visible mount represents only ten (10) percent of the whole, to wit, there is a ninety (90) percent unseen portion beneath the visible portion. To edify the value attainment, ISCM instructively prescribes a mindset, thinking, activities, operations, management, and leadership that thrives on the effective management of the unseen. The concept of ISCM presumes that sustainable value, which is the ultimate goal of its action, is attained when the hidden factors are;

- Identified appropriately

- They are well sequenced and organized

- They receive the needed attention (prognosis) and diagnosis

- They receive the needed attention (treatment or the preferred action)

- They receive the right attention (the proper and appropriate implementation plan)

- The rightful outcomes

- Need for Continuous Reviews (Effective monitoring and evaluation)

- The principle of “No Waste” – ISCM operates under the ethos called ‘When others say it is waste, that is the initial input for our value’ under the banner of Nothing is called waste.

The Platforms of the Definition of Integrated Supply Chain Management

The definition of Integrated Supply Chain Management takes its roots from the following platforms;

- Objectives: The generation point of anything in ISCM activity starts from the original goal(s), through to the appropriate processes and the needed requirements, for successful outcomes of the original objective.

- Strategic Thinking and Mindset-based

- Value Chains and their transition processes into Expected VALUE

- Demand and Supply of Resources

- Linkages from ideas to successful implementations, up to the attainment of the expected outcomes (Transformation)

- Leadership & Sustainability

The difference between Process Based Supply Chain Management & Integrated Supply Chain Management. See below some baseline characteristics.

| Process Based | Integrated Based |

| This operates on silos bases: For example, stand-alone operations and value for identified supply chain management process functions such as Planning, Sourcing/Procurement, Inventory/Stores/Warehouse, Manufacturing/Operation, Logistics/Transportation, Distributions, Reverse processes, etc. | This operates on centralized bases: this operates on the synchronization of all identified supply chains management functional activities (end-to-end). Its value is from the composite outcomes of all the identified functions. |

| It is activity based | It is centered on developing and having the right ISCM Mindset and Thinking and not just the Activity |

| It is operational to tactical (Micro) linkage Based | It is Strategic (Macro) linkage Based, even though it works along with the micro activities. |

| It focuses on the management of demand and supply of goods and services | it focuses on the demand and supply of enterprise resources |

| It focusses on the Technical Knowledge of the operations and the management of Supply Chain Activities | It is centered on both the Technical Knowledge and more importantly the Applications of the Principles, Methods, Practices, and the models of the Composite (end-to-end) Technical Knowledge. |

Integrated Supply Chain Management strictly posits and operates firmly on end-to-end consolidation of the supply chain functional activities, which in the scheme of things is called PROCESS BASED SUPPLY CHAIN MANAGEMENT (Technical). Additionally, and most importantly, it focuses on the APPLIED knowledge and practice by using the technical principles, methods, and the mindset/thinking approaches (models) to all fields of knowledge, practices and endeavours to create sustainable value.

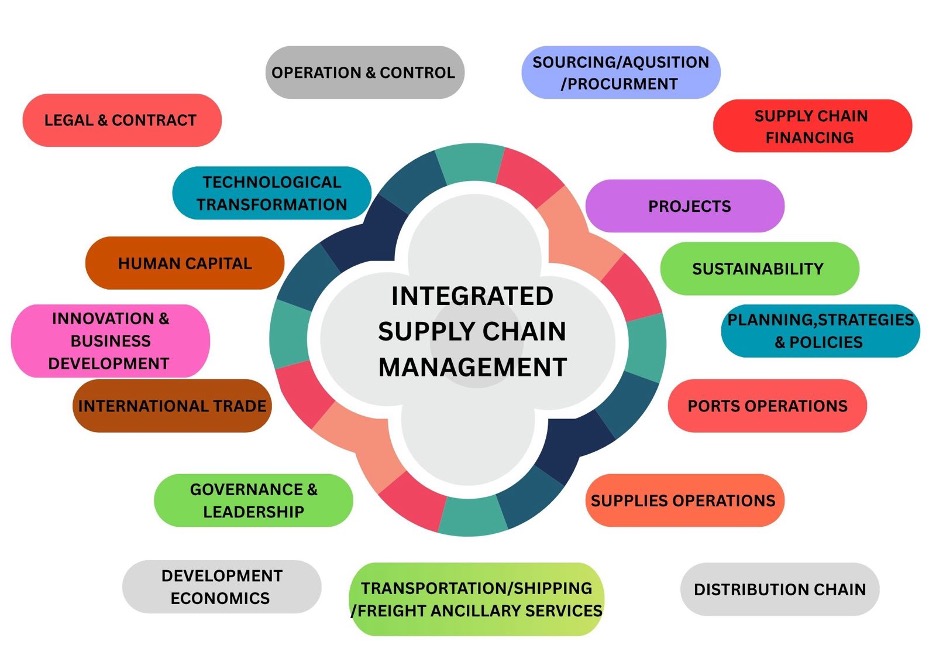

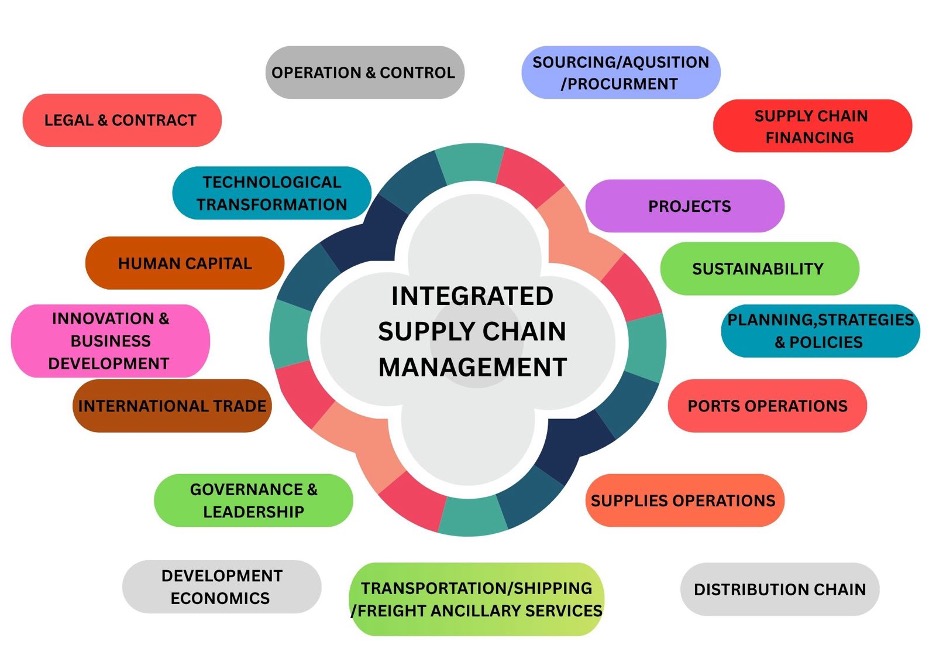

The Seventeen (17) Value Streams (Value Chains) that ISCM is Made up of.

The picture here 17 Value Streams which serve as a strategic tool to close the gaps and enhance optimization in the practice and management of supply chains to attain Best Value.

Integrated Supply Chain Management projects the following sustainable values.

- VISIBILITY

‘Become Visible at all times’ – The meaning of our visibility has two components; Structural & Product Visibility. Our structures must stand in leadership, apt at all times to develop sound and innovative systems to stand the tests of time with the aim of ensuring Best Value for Money. Our Products must deliver a high level of sound professional standards full of leadership and innovations at all times to drive Nations, Corporates and Organizations to attain their strategic objectives through effective supply chain models and practices. – SIMPLY PUT: ‘The Quality that emit from us.

- ACCEPTABILITY

Become Acceptable at all times – Our endeavors must be reflexively identical. We seek to resolve challenges and develop standards that are relevant to sustainable growth, we become the preferred option at all times. – ‘Always the preferred one’

- RELEVANCE

Become Relevant at all times – Our sustenance is dependent on our relevance. Our mission of always focusing on end-to-end Supply Chain Management development, positions us to become most relevant at all times. CISCM is all about researching and developing value and Integrated supply chain activities to provide sound and reflexive knowledge, providing support and actively participating in National and Corporate growth, developing local contents (Ghana, Africa, Developing Nations) case studies for effective benchmarking and recognizing effective stakeholders at all times. These will make us globally relevant as a supply chain management civilization. – ‘Our futuristic mindset makes us the most relevant’

Integrated Supply Chain Management Framework

This practice Framework is to ensure effective and ef?cient deployment of work structured to deliver BEST VALUE. Below are the non-negotiable and non-compromising steps;

- DEVELOP; The role of supply chain management in the idealization, conceptualization of ventures, projects, tasks, enterprise, policies among others is key and core. This ISCM framework directs the inclusion of supply chain mindsets and its core values in the initiation of any value stream. Therefore, it is a must that users, subscribers, practitioners, partners, and systems of ISCM depicts these core features. – Lead, Initiate, Create, Innovate, become the core reference for all Resources

- PLAN; Planning the sourcing, making, distribution, support and disposal activities constitute always a critical and crucial function for ISCM users and subscribers. Developing frameworks, sub-frameworks, standards and appropriate and sufficient suitable roadmaps before executions of any kind is a MUST do.

- SOURCE; Developing appropriate and sustainable sources fit for purposes and the effective management of sources suitable for needs, with the view of supporting optimisation and improvements of practitioners and subscribers.

- MAKE; This phase is paramount and represent core function for ISCM’s practitioners because the collateral business, and the corporate output and performance, is derived from this activity as the core operations of the enterprise. This is the most crucial position in an enterprise because it is where demand and supply interact and where best knowledge and sound practises are supposed to be exhibited to make the enterprise relevant and sustainable.

- DISTRIBUTE; The consumers are the prime factors for any enterprise and as such it must be given the appropriate weight, to ensure that consumers’ demand and the correspondent supply matches or are aligned. Any inconsistency(ies) is a loss to the enterprise and poses a grave danger for the sustenance of the enterprise. Therefore, a high level of scientific based approach, strategies and excellent services must be employed to attain the appropriate share of the market that the enterprise should own.

- SUPPORT; integrating supply chains for best value for money is our utmost responsibility. Therefore, providing all the necessary resources, providing backward and forward linkages to resources, providing assurances for compliances and risks, delivering to the terms and conditions, and expectations of engagements for our internal customers, suppliers, customers and all stakeholders is our overarching and primary goal. Sharing knowledge and providing linkages for knowledge sharing, committing to the appropriate technologies and influencing enterprises for the appropriate technologies, sharing and practicing global sustainable development goals to sustain enterprises is everyone in ISCM’s goal.

- TRANSFORM; In ISCM’s it is firmly believed and stands on the ideals of ‘Nothing is WASTE’, To wit operations of users and subscribers do not have a tipping point, even though there is disposal in mind. Dispose does not mean destroy, savagery, terminal use. It relates to taking a reverse action to make an outcome useful until it can no longer be used. No material, component, article is waste, the waste for others is the beginning of our development (REVERSE). Re-cycle, Re-use, Re-engineer, Re-tool, Re-program among others is our philosophy. We always aspire to be GREEN.

To Be Continued…

The post Continuation of the Integrated Supply Chain Management (ISCM) Concept appeared first on The Business & Financial Times.

Read Full Story

Facebook

Twitter

Pinterest

Instagram

Google+

YouTube

LinkedIn

RSS