By John Baptist Walier KABO-BAH

Ghana’s post-harvest losses (PHL) in staple cereals are not occasional slippages; they are structural frictions that erode farm incomes, weaken food availability, and dampen agribusiness investment.

Best available national estimates suggest double-digit, economy-relevant losses for major cereals with clear shocks transmitted along supply chains from farm to market (APHLIS, 2021).

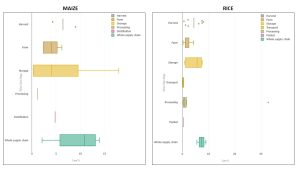

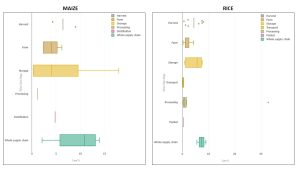

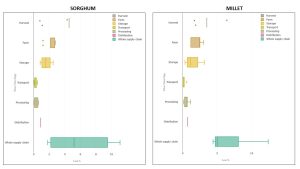

Fresh analysis of Ghana’s FAOSTAT data (2000–2021), summarised as median loss rates by value-chain stage, reveals a consistent pattern across maize, rice, millet, and sorghum. The boxplots below show the harvest losses forming the largest, most consistent block across crops, while storage especially for maize and rice has the widest spread.

Maize

- Whole chain: median 12.3%

- Largest stage losses: Harvest 6.4% (tight clustering) and Storage 3.65% but with very high variability (upper range to ~29%). Farm-level handling averages ~4.0%. Transport and processing are comparatively low.

- Implication: Rapid gains come from better harvesting/threshing protocols and upgraded storage (hermetic bags or cribs/silos, moisture control, aflatoxin management). Reducing storage variance lowers working-capital risk for aggregators and improves the bankability of warehouse receipts.

Rice

- Whole chain: median 7.4%.

- Largest stage losses: Storage 5.64% and Harvest ?4.4%; farm handling ~1.25%; transport minimal. Notably, processing losses are usually low (?0.9%) but occasionally spike (outliers >30%), reflecting “wrong-place, wrong-setting” milling and poor paddy conditioning.

- Implication: Rice needs storage upgrades plus harvest/threshing quality control, and selective investment to de-risk milling (moisture control, pre-cleaning, appropriate machine settings).

Millet

- Whole chain: median 5.0%

- Largest stage losses: Harvest 3.5% and Farm 2.5%; storage is modest (~1.12%) with narrow spread; transport/processing are minimal.

- Implication: Field-level practices dominate loss in the millet chain. Need to prioritise harvest timing, clean threshing, and rapid field drying. These are low-cost fixes with quick returns for farmer groups (especially vulnerable groups) and buyers sourcing at scale.

Sorghum

- Whole chain: median 5.2%.

- Largest stage losses: Harvest 4.6% and Farm ?2.2%; storage typically ~1.5% with modest spread; transport/processing are low.

- Implication: Like millet, sorghum losses concentrate before grain reaches the storage stage. Strengthening harvest discipline and early post-harvest handling stabilises supply volumes for breweries and food processors relying on sorghum contracts.

Investable Actions to Reduce Food Loss and Waste in Ghana’s Cereal Value Chains

Introducing District Post-Harvest Clinics (PHC) integrated with Farmer Field Schools (FFS)

PHC with FFS standardise good practices should be delivered through MoFA extension and private input dealers, and timed to harvest windows.

Through this, field teams coach harvest discipline; verifying physiological maturity, clean threshing, off-ground drying on tarpaulins, and rapid moisture testing.

The approach covers all four cereals, with emphasis on millet and sorghum, where field practices are the principal loss drivers.

Moreover, demonstrations could explicitly apply the Voluntary Code of Conduct (VCoC) on Food Loss and Waste and use the FLAPP data-driven app design by FAO to capture in-field stage-specific loss data and guide immediate interventions.

Upskilling farmers and district agricultural extension personnel will help translate these insights into routine standard operating practices (SOPs) across the regions.

Enhance Storage Modernisation and Mycotoxin Management

Upgrading storage from household to aggregation using hermetic solutions (PICS or equivalent bags), pallets, and basic aeration, alongside a straightforward quality-control regimen (grading, cleaning, routine moisture checks, and integrated pest management) protects weight, quality, and safety while reducing aflatoxin risk.

Proven models such as Saving Grains demonstrate how trading solutions can enhance quality, traceability, and contamination control to create real value for farmers. Scaling such approaches, paired with continuous capacity building for farmers and value-chain actors will embed these practices system-wide.

Crucially, the Ministry of Trade and Industry and the Ministry of Food and Agriculture should partner with private-sector operators to expand the Saving Grains solutions approach, turning today’s diagnostics into measurable, investable results.

Promote Harvest-to-Milling Quality Chain

Farmers or cooperatives can make sure paddy reaches the mill clean and at the right moisture (12–14%) to avoid sudden, costly spike losses, especially in the rice value chain. District drying and conditioning hubs can also offer affordable, pay-as-you-go drying to that specification.

On the mill side, basic pre-cleaning and routine machine calibration, supported by operator training, keep quality consistent. This model pays for itself: when grain is dried and milled correctly, mills get higher recovery rates and fewer rejected batches, which covers service costs and farmers benefit through more reliable purchases and better prices.

As we mark the International Day of Awareness of Food Loss and Waste (29 September), Ghana has an immediate, practical path to higher food availability, stronger farmer incomes, and safer grain. By enforcing harvest discipline, securing moisture-safe storage, and conditioning rice before milling, we can deliver verifiable reductions in losses by 2026 and set a standard for West Africa.

The Author is the (Business Development Strategist & Agribusiness Management Professional). Email: [email protected].

The post Cutting the leak: Priority actions to slash FLW in cereals by 2027 appeared first on The Business & Financial Times.

Read Full Story

Facebook

Twitter

Pinterest

Instagram

Google+

YouTube

LinkedIn

RSS